Bassoon Reed Making Machines

Posted by K.C. Chai, DMA on Mar 23rd 2019

My Reed-Making Machine Background

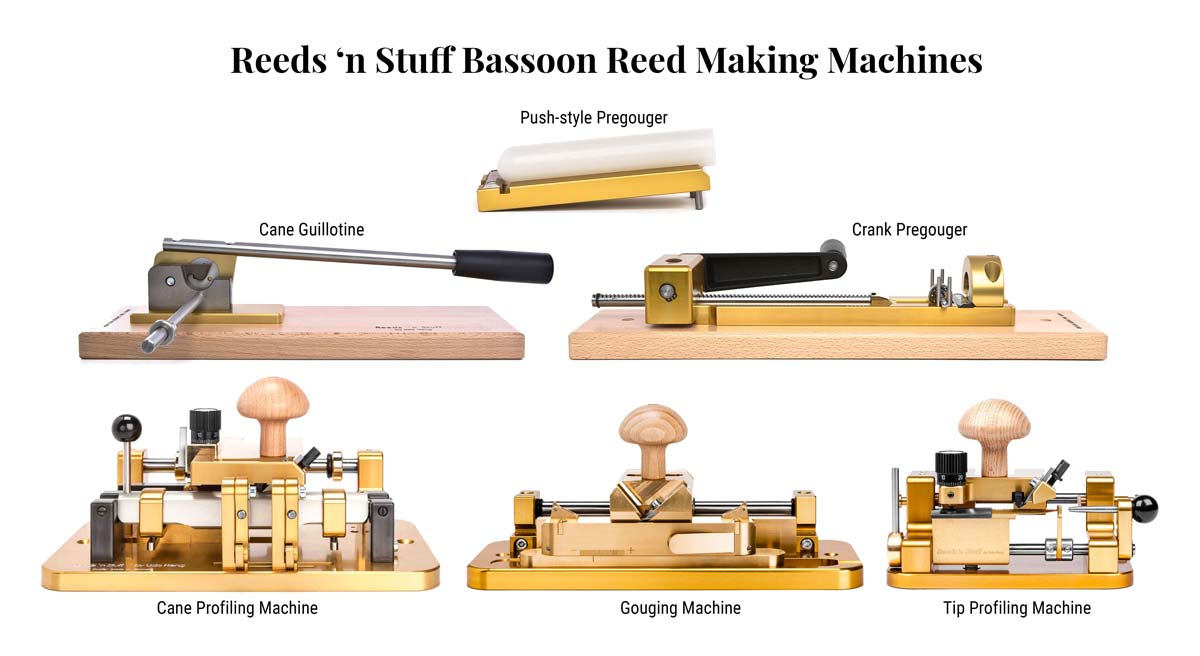

A few weeks ago, we at Hodge Products had the opportunity to host Udo Heng, oboist and owner of the Reeds 'n Stuff business (RnS), located in Germany. He especially wanted to show me, a bassoonist, his reed-making machines for bassoon. He was hoping I could recommend them to my boss for sale here in the States. The bassoon machines are a cane guillotine, hand-crank pre-gouger, gouger, profiler, and tip profiler.

During my DMA at UNLV, I found a used Rieger tip profiler which I bought immediately. A year later I found a player unloading his guillotine/gouger combo and profiler, as he changed industries. I bought that too. I have happily used my Rieger machines for the last 8-10 years. Caveat: My machines are older than 10 years, and Rieger may have addressed the details I'm discovering that are really nice about Reeds 'n Stuff now. The purchase of Rieger machines was recommended by a couple of teachers over the years, hence I jumped to buy them when they became available.

The main point to keep in mind is that older-model Rieger machines are the baseline from which I formed my opinions. There is nothing wrong with my Rieger equipment. I have been very happy with it. But the focus on this blog is the new Reeds 'n Stuff machines and what I especially noticed.

Preparation for Udo Heng's Visit

Prior to hosting Mr. Heng, I spent time with my equipment again, to keep it fresh in my mind how everything worked. First, I split my tubes with an old dull knife. (I have never bought a formal tube splitter.) However, Rieger and Reeds 'n Stuff both make splitters. The Reeds 'n Stuff splitter is a base on which is mounted a plexi-glass tube. In the center of the tube is the four-way upward-facing blade. The tube is placed at the top of the blade, and you use the provided hammer on the tube to split. The nice feature is that the tube "catches" the cane.

The Rieger splitter is a medium-weight metal tube. It has an inscribed line on the surface, which is also nice, so that you can line up the flattest part of the cane, if you wish. I held the tube in one hand and the splitter in my other hand, and held with the up end of the cane at the splitter blade. Then I hit the cane on a table or desk, forcing the cane against the blade. Both tools are faster than my dull knife method, and both splitters are fine products. I have no real preference between them.

Then I soaked up a good amount of cane, which I processed on my equipment to various levels, so that we could focus on Mr. Heng's machines however he saw fit. I also brought a few blanks to finish on the tip profiler. All this being said, I was a bit skeptical on what I would think about the RnS products, due to others' opinions about the Rieger products along with my 10+ years using Rieger machines, but I also needed to be willing to hear him out regarding his products. So I got to process cane with him using his machines. And...

Pause for dramatic effect.

Wow! Everything I tried was simpler, smoother, quieter, and faster than my Rieger machines. This could be in part to my Rieger machine blades needing to be sharpened. I also may need to oil the mechanisms on some of my machines. Nothing was wrong with my personal machines, but each RnS machine was impressive! I found it to be in the details where the differences came to light. I'll give a brief description of each of the Reeds 'n Stuff machines.

Guillotine

A guillotine is used to cut the split lengths of cane to length, usually 120mm, though some choose other measurements. Both machines can be adjusted for the cutting length. The cane should be dry when cut here for best results. The critical difference between my Rieger and the Reeds 'n Stuff is the actual blade that cuts the lengths. Rieger uses a triangle/arrowhead shaped blade, versus the RnS blade which is round. The Rieger triangular blade does not put even pressure on the cane while cutting it. The point places extra pressure in the middle of the inside curve of the piece of cane. So any excess length to the piece of cane that is being cut off ends up split or cracked straight up the middle. This crack destabilizes the cane against any possibility of using the excess. Even if that crack could be overlooked from a forming perspective, the crack ruins the piece of cane when you go to gouge it. I know this; I tried to keep that cane. It broke at different stages between gouging and profiling, and sometimes during the pre-gouging. The measured portion of the cane piece is fine.

The RnS blade, being round, puts even pressure on the wood, allowing the portion in excess of 120mm (or your chosen length) to remain usable if it's long enough. This is distinctive because we now sell Alliaud tube cane for bassoon. As many as half of the tubes are extra long, and many are long enough to get two 120mm sections. But one half is on the measured side, and the other on the "waste" side. Because of the round RnS blade, the waste can be preserved for usage if it's long enough. When you buy cane by the pound or kilogram, if it is extra long, you are paying for weight of cane that will not be recovered on my Rieger machine.

If Rieger has updated this detail on their guillotine in the time since designing my particular machine, I am unaware of it. No publicly available pictures of the machine show the blade. So I presume the newer Rieger guillotines are still the same in terms of the blade choice.

Finally, though subtle, I felt like I exerted a bit less effort to cut my pieces to length on the RnS versus my Rieger.

I do like Rieger's design of including the guillotine as part of the gouger, for ease of having it all there in one item. However, even though Mr. Heng has them designed as two separate machines, he sells them both together or separately. The only choice here is based on whether or not you need a guillotine by itself, already owning a gouger, or if you need both. If you need both, save a little money and order them as a combo. Not all American vendors sell them as a combo, so do your research.

Pregouger

The Pregouger removes wood or pulp from the inside of the curve. There are two basic styles of pregouger. 1) The one pictured above with a hand crank which has a slider that pushes the cane against the blade. 2) and the hand push-style, pictured below. Both are available from Reeds 'n Stuff.

Push-Style Pregouger

The pregouger has legs or feet that hold onto the edge of a table or desk. You place the flat side of the pusher against the cane and push it against the blade. The push-style is cheaper but more effort to use.

Crank-Style Pregouger

In comparing my non-RnS push style pregouger to the RnS crank-style, the difference really is night and day! One trick to keep in mind with both is to lightly use one hand (for me the left) to keep the cane in the bed. This makes sure that it properly passes under the blade. A pregouger is not strictly necessary. A gouger will remove this wood, but it does so at the expense of wearing out your gouger blade much faster. Those blades are usually not cheap, whereas pregouger blades are usually much easier to replace, should you need to.

The hand-crank RnS machine is simple, almost effortless, as far as pressure you have to apply. But don't be in too big of a hurry, as this leads to some sloppy work. The only drawback I can see in the RnS design is that the last piece of cane to be run through the pregouger stops with about an inch of material yet to pass through the blade area. Then you take a piece of cane, already pregouged, and run it again, just far enough to push out the stuck piece, and then pull the already cut piece backward along the bed. It's simple to do once you've done it a few times, but it seems odd at first.

Shims are included with the crank-style pregouger so that you can adjust the amount of wood to be removed. Use either pre-gouger with soaked cane. Also included is a C-style clamp that can allow you to lock down the machine to a desk.

Here's the video on the Hand-Crank Pregouger.

Gouging Machine

Following the use of the pre gouger is the gouger. This machine continues to remove wood from the inside of the curve of a piece of wood. It is set to ultimately leave a gouged piece of cane at a prescribed thickness. It comes with instructions to explain how to adjust the settings to customize your preferences. Pictured on the right center is a lever that moves a piece with teeth at the right side of the bed in which you place the cane. The teeth hold the piece of cane at the ends, and then levers on each end hold the cane down from the top into the bed. Because of this design, the cane is held down in the bed better on the RnS gouger than on my personal Rieger; the cane shifts quite a bit on my machine.

The actual blade that removes the wood material is directly below the handle in the picture. Kept well-oiled, the blade moves along the horizontal bar so smoothly and easily that it requires almost no effort, especially from your arms to push the blade down to use it. The included instructions describe how to adjust the thickness of the gouge. It also comes with pre-drilled holes so that it can be mounted to a base or a desk. This is a nice touch should you want it set up that way.

The gouger produces either an eccentric gouge or a concentric gouge. Both styles of gouge are supported by major players and teachers. This detail comes down to personal preference and experiences with different machines. Contact us for availability of the style on hand. A special order is also possible and relatively quickly received.

Cane Profiling Machine

The bassoon profiler removes the bark from the piece of cane over the area that becomes the blades of the reed. The piece of cane is placed and held on to the barrel by metal bands with a tightening screw (shown below). The barrel, which holds the cane during this process, is not round but a modified rectangle (barrels also shown below). This change removes weight and bulk from the barrel, and it fits in the hands easier, making it easier to set the cane and tighten it to the barrel. The ends of the barrel are easier to place and remove than that of my Rieger. The screws are now bar-shaped, and are thus easier to grip and control. This is actually thoughtful and much easier to use than the round screws. That is a really nice change.

The blades that score across the cane to create the center fold and the ledge have locking arms that keep them (the blades) almost stationary until ready to use. It then releases them smoothly and easily but without the risk of accidentally cutting yourself by accident. It is a simple but elegant solution to a problem you didn't even know was a problem.

The main blade can be adjusted and removed to be resharpened if need be. There is also an adjusting knob to fine tune the thickness of the final profiled piece of cane. It's the small black knob on top. My older Rieger profiler does not have the adjusting knob, however the newer model, released a few years ago, DOES now have this capability. It's nice that Rieger has updated this point. With the provided instructions, you can also adjust the angle of the profile, though I have not experimented with this detail.

Overall, the profiler was incredibly smooth in terms of use and the resulting reed blade area where the bark was removed. It takes very little effort to move the blade across the cane. Both the angle control handle and the blade handle are removable. All in all, this machine was just easier and nicer to use than my Rieger profiling machine. I must admit that a newer Rieger profiler might now equal the RnS.

Tip Profiler

The tip profiler is used to finish or largely finish the reed. After the profiled cane is built into a blank, including shaping, scoring, beveling, forming, wiring, and wrapping, and the tip clipped, it is ready for the tip profiler. The mandrel that holds the reed is on the right while in use, and can be stored for transport on the left. A nice nylon travel case is included with a new purchase. When the reed is place on the tongue or plaque portion, up to the inscribed line, the mandrel is inserted into the rotation arm (connecting to the rotation handle on the left), and then the clamping arm is placed over the tube of the reed. At that point you begin to move the handle and blade mechanism over the reed.

My Rieger tip profiler finishes the blade end of the reed, but only about 1/3 of the blade, closest to the tip. The RnS tip profiler finishes half to 2/3 of the total blade. This seriously reduces the time you need to spend in doing knife work to finish your reed. There are several templates available to get you to the reed design you like. See the website for more info on the templates offered. The blade carriage to remove wood works and moves like butter. It was incredibly smooth in action, almost effortless, and the blade surface cut was also super smooth.

The nicest feature in terms of adjustment is the dial. One millimeter increment as marked on the dial changes the finished measurement by 1/10 ( 0.1) mm. The dial can be used for overall adjustment or locked with an Allen wrench and set up to measure the actual thickness left at the tip. Included instructions will tell you how to make sure the numbers on the dial are accurate.

All in all, this, of all of the Reeds 'n Stuff machines I tried, was the most impressive. Not that each machine wasn't impressive in its own right. But if I could only buy one machine right now, or sell and trade up, this is the first machine I would get. It was that much better than my own Rieger tip profiler.

Rieger, in recent years has created a replacement part for the blade carriage portion of their tip profiler with a similar adjustment knob. It's not cheap, and you either buy the part to install yourself or your ship the machine to Rieger in Germany for them to replace and set up for you. And then you have no access to your tip profiler for the duration that it's gone. This situation could be cause for concern. The last note-worthy aspect of the RnS tip profiling machine is that an additional set can be purchased to modify the machine for contra reeds.

Concluding Thoughts

I have long loved, and been proud to say I owned, my Rieger reed-making machines. They are work-horses: built to last, built for abuse. But they are not equipped with the most recent modifications. Mr. Heng's thoughtful modifications to machines with a similar function and similar basic design make for standout products. If I could afford to do so now, I'd buy all-new machines, and they would all say "Reeds 'n Stuff." As it stands now, the Reeds 'n Stuff machines have been made easier to use, smoother to operate, cut smoother for results, and just impressive enough that I want them. Now I just need to find the right way to finance them, but I digress. If you're in the market for reed-making machines for yourself or private studio, do consider Reeds 'n Stuff products; I don't think you'd be disappointed.