Caring For and Using Your Shapton Ceramic Stone

Posted by Ann Hodge on Sep 26th 2019

It is important to care for your ceramic stone properly to get the longest use out of it and for it to do the best job sharpening your knives. The following paragraphs come directly from the care and use instructions given with Shapton ceramic sharpening stones.

Shapton ceramic sharpening stones have been carefully developed to be low maintenance. Please observe the following guidelines while caring for your stones.

Guidelines

- Do not leave the stone in water. Doing so may damage the stone. To use the stone, just splash (or spritz) water on it as needed.

- Do not leave the stone in the sun. Store the stone indoors, out of direct sunlight instead.

- Do not dry the stone with a fan. Doing so may cause hairline cracks to appear on the surface of the stone.

- Do not subject the stone to extreme temperature. Store the stone indoors at room temperature.

- Do not wash the stone with hot water. This may damage the stone. Use cold or lukewarm water instead.

- Do not wash the stone with soap or detergent. This may damage the stone. Use water instead.

Loading Up or Impaction

If your stone seems to glaze over, it is impacted with many small particles of steel or iron, and possibly oil. This is called "loading up". Shapton ceramic stones have been carefully engineered to resist loading up. However, using the stone too dry without water will cause it to load up. Keeping fresh water on the stone during the sharpening process will cleanse the surface.

Storing Your Ceramic Stone

When finished with the stone, store it in the plastic container that it came in. This will help prevent the stone from developing hairline cracks. These cracks will not affect the performance of the stone, however.

This stone comes with a foam insert in the box for shipping. Please discard this foam insert before you begin using the stone.

Sharpening Instructions

First, remove the stone from its box and place it on a base. This can be the top of the box itself. Put the printed face of the stone down.

Apply water to the top of the stone with a spray bottle and begin sharpening. During sharpening, continue to apply clean water to the surface. Try to work the entire surface area evenly. The more evenly you work the surface, the longer the surface will remain flat between flattening. For more detailed instructions, purchase The Jende Book of Sharpening Double Hollow Ground Reed Knives by Tom Blodgett.

Occasionally lap the surface of the stone using the Shapton Lapping Plate and powder to maintain a flat sharpening surface.

Shapton ceramic stones require very little pressure when sharpening. Let the stone do the work. You will find that the stone can remove material very quickly with a minimum of pressure. Keep your strokes light and consistent.

Always clean your tools and stones with water before moving up to the next stage in your process. Carrying coarse grit or other materials under your fingernails can cause errant scratches in your surfaces. These stones are very dense and particles will remain on top of the surface if not cleansed carefully.

The most important concept when using the Shapton system is achieving consistency at a given grit level before moving up to the next fine stone. At the 2000 grit level, your stone should already be perfectly shaped from previous coarse grit sharpening. It is ineffective to attempt to rehsape your tool at any finer grit level. If you have built a good foundation at the coarse grit level, very little work will be required at the finer grit levels.

Sharpening is an attempt at perfection. The most interesting aspect of sharpening is the reflection of the infinite.

Lapping Your Shapton Ceramic Stone

Compact Lapping System

This Shapton Lapping Plate and powder will help keep the surface of your stone flat. Keeping your stone flat is the key to successful sharpening, and is very easy to learn.

To Use:

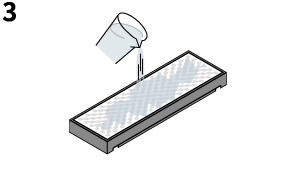

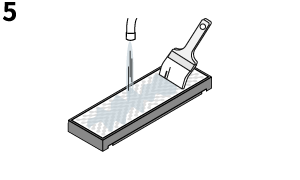

Pour water onto the plate until the grooves are evenly filled. Then, evenly distribute the powder across the plate.

Place the stone you wish to flatten upside down on the surface of the lapping plate, then move the stone in an "X" pattern, making sure to use the whole plate.

Powder

If the stone you are flattening is very uneven, begin with the coarse powder. Use the lapping plate until the surface of the stone is flat. Clean the lapping plate off with water, and then use the medium powder. If the stone you are flattening is not very warped, skip straight to the medium powder. Use the fine powder to create the finished surface on the #5000, #8000, #12000, #15000, and #30000 grit stones. If you lap regularly, you may never need to use the medium grit powder with the polishing stones.

Diamond Lapping System

Another option for lapping your medium and fine ceramic stones is the Diamond on Glass Lapping Plate (DGLP). An advantage to this lapping plate is that you don't need to use powders, only water. The DGLP uses glass for its base, and this is what produces such high precision on the resulting sharpening stone plane.

To Use:

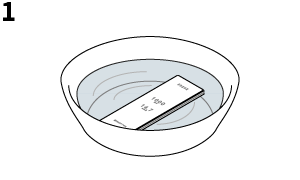

Immerse the Shapton ceramic stones you are intending to lap in water for 2 to 3 minutes before starting work on them. When lapping non-Shapton stones, you should ensure the stones absorb plenty of water first.

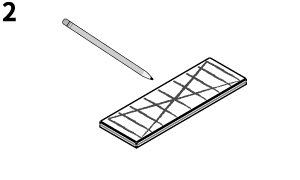

As a guide, use a pencil to draw a grid on the stone surface to be flattened.

Place the plate somewhere stable and splash it with water.

To lap a stone, lay it on the lapping plate and slowly slide it forwards and backwards, then diagonally, using the whole surface evenly. Any time slurry accumulates in the grooves, rinse it off then resume lapping.

You can also lap a stone by laying the lapping plate on the stone.

In this case, you should slide the lapping plate forwards and backwards, then diagonally. Parts where the lines get erased show where the lapping plate has made contact, i.e. where flattening has been performed correctly.

Once you have finished lapping, rinse off any slurry promptly before putting the plate into storage.

We also recommend using a brush at this time.

Precautions

- Never sprinkle abrasive agents or other loose grains between the lapping plate and stone.

- The DGLP surface (the lapping face) contains a thin film of metal on a sheet of glass. Handle this carefully, as its resistance to shocks is limited. If cracked or chipped it could be dangerous and should not be used.

- Only use the DGLP for lapping normal stones (do not use it on stones incorporating diamond abrasive grains). Also, do not use it to scrape blades, metals or other materials.

- This DGLP is capable of lapping stones up to 30 microns (500 grit or above). Do not use it on rougher stones, as that would dramatically reduce its usable life.

- Do not use hot water when lapping. Immersing it in hot water and then suddenly cold water creates a risk shattering.