Guide to Choosing an Oboe or Bassoon Reed Knife

Posted by Tim Hodge, edited by Clair Cangialosi, DMA on Jul 21st 2025

When you are looking at purchasing a new reed knife, the options can be dizzying. At Hodge Products alone, we have nearly 60 different knives. These knives vary in the shape of the blade, quality of steel, balance, and ergonomics. What (almost) all reed knives have in common is a straight blade of high-quality steel that can hold a sharp edge.

This post will take you through everything you should consider before purchasing a new reed knife including:

- Student vs Professional Knives

- Types of reed knives and reed knife alternatives

- Anatomy of a reed knife

- Steel quality and hardness

- Knife handle materials

- Balance

- Right vs left-handed setup and sharpening basics

- Our Recommendations

- Works Cited

Whether you’re a seasoned pro looking for an upgrade or a student shopping for your first reed knife, we’ve got you covered! Keep reading to learn all the details or jump to the bottom for a side-by-side comparison of our most popular knives.

Student Vs Professional Reed Knives- What’s the Difference?

The main factors which separate student reed knives from professional knives are the type of steel used for the blade and the price point. Anyone can use any knife- it depends on your budget and personal preferences- although certain knife styles do require some extra finesse to get successful results.

Student knives, such as those we outlined in our post, Oboe and Bassoon Reed Knives: What First Time Buyers Need to Know, are typically made of softer steel, which makes them easier to sharpen and use with minimal setup. Our knives in this category are all under $65.

The professional knives that we carry are priced at $65 and above. The knives in this category are made from harder steel, which can hold a sharp edge longer, but are also more difficult to sharpen. The details of knife material choice will be discussed below.

What Are The Types of Reed Knives?

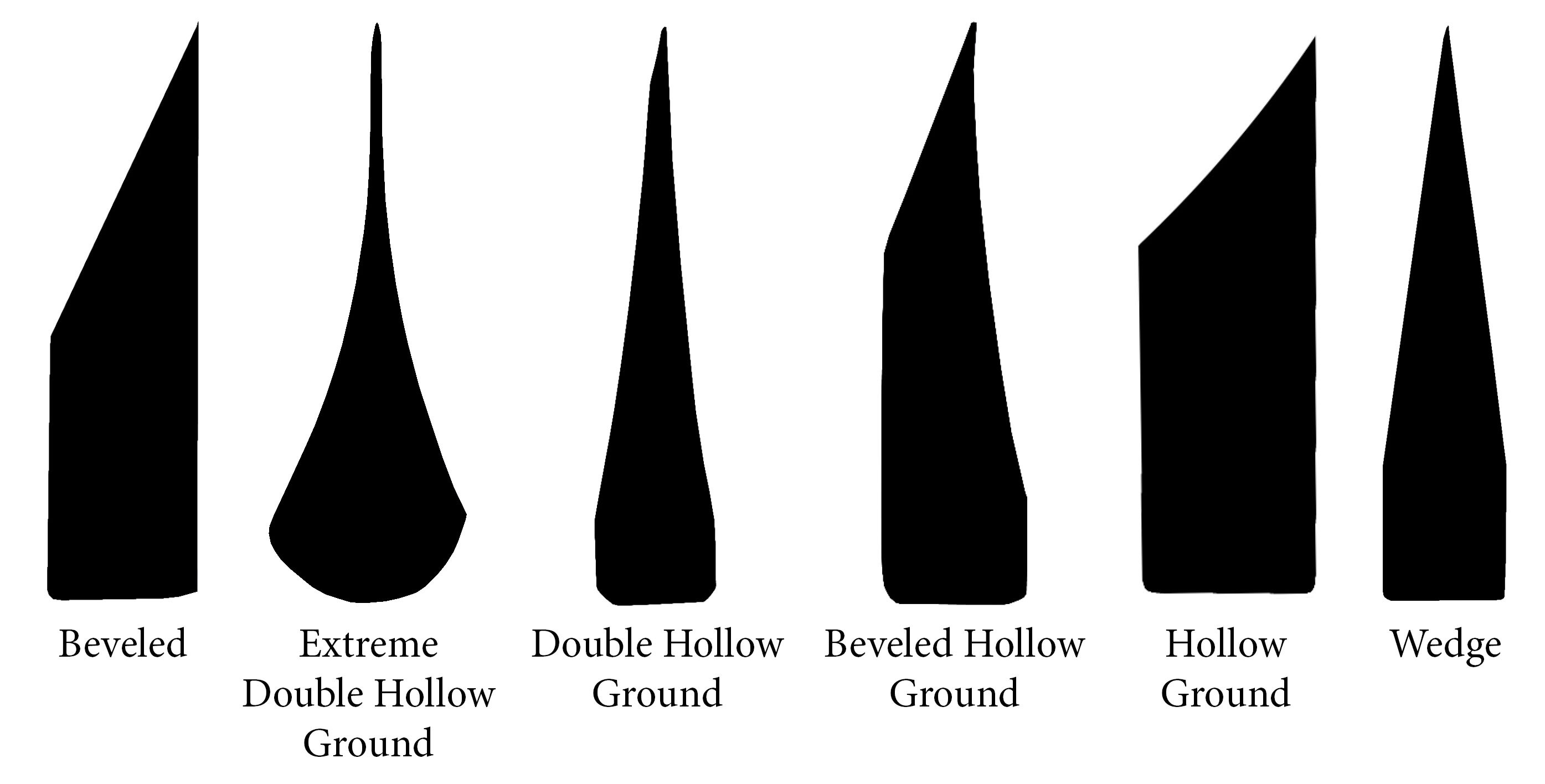

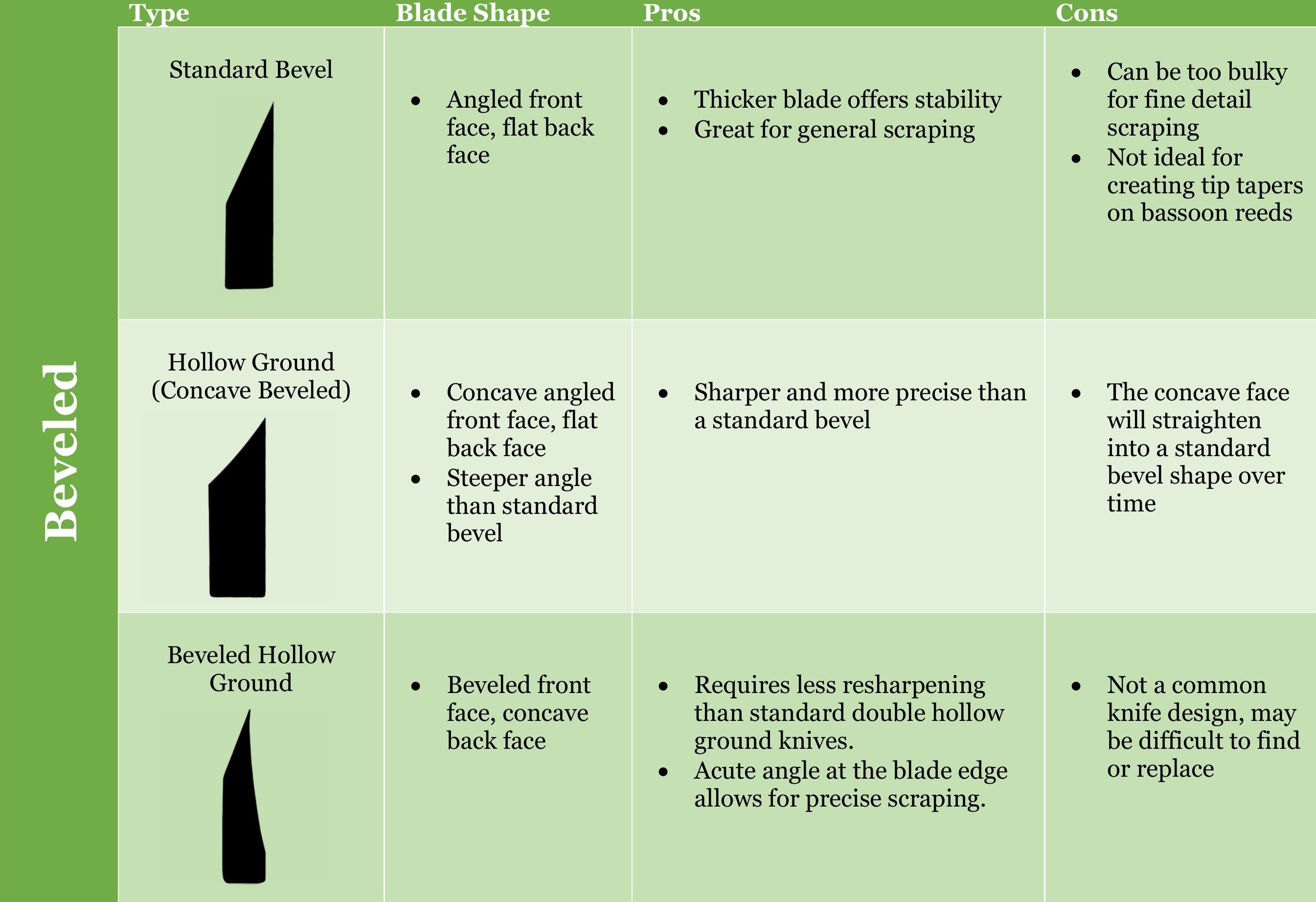

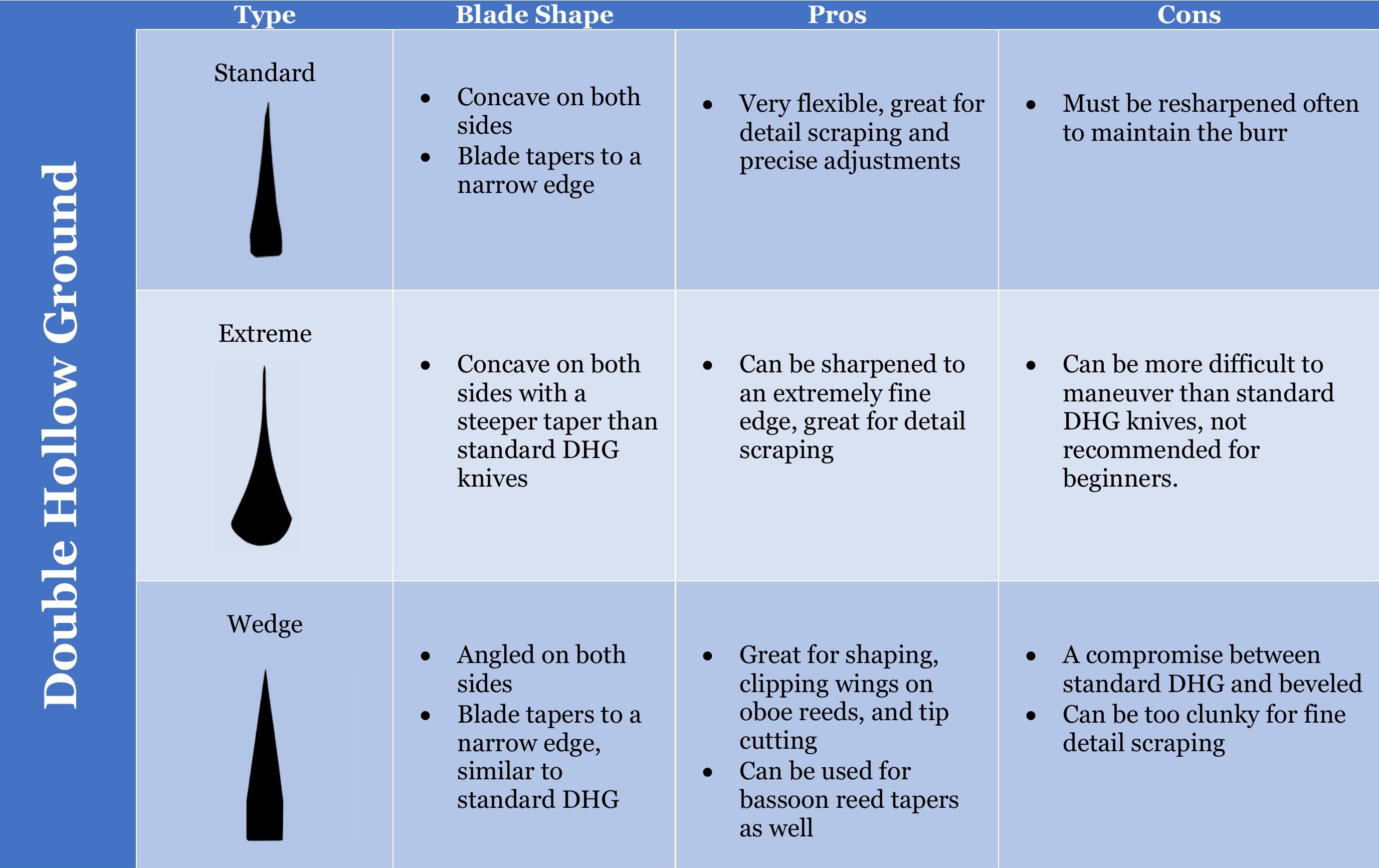

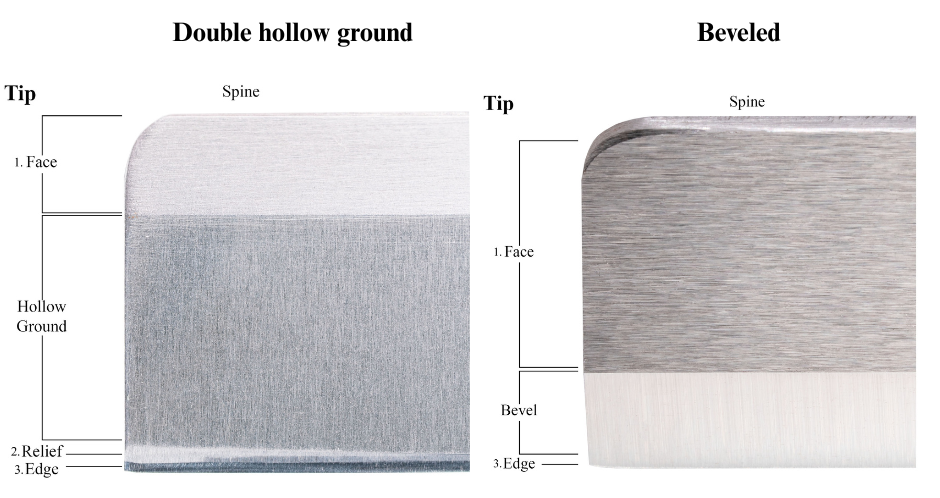

Understanding the primary styles of reed knives, how they work and what each is used for can narrow your search tremendously. The two primary types of reed knives that we carry are Beveled and Double Hollow Ground. There are also several hybrid knife styles, which we have grouped with the most closely related primary style for ease of comparison. Figure 1 shows profile views of the different types of knives.

The two sides of a beveled knife are asymmetrical, with a combination of flat, concave, or angled faces. A full list of the beveled knives we carry is available on our website.

The blade of a Double Hollow Ground knife is symmetrical. Both faces are concave and taper to a thin edge with a burr. A full list of all the double hollow ground knives that we carry can be found on our website.

Alternative Knives

Ceramic Knives

Ceramic knives have become popular in the culinary profession because they maintain a sharp edge for much longer than a traditional steel knife. However, due to the nature of the material, ceramic blades have trouble holding a burr, making them better suited for cutting than scraping. This makes them a great option for cutting the tip off the reed or for shaping. The Reeds ‘n Stuff Ceramic Knife is similar to a double hollow ground shape.

Note: Ceramic knives must be sharpened on a diamond stone.

ReedGeek

If you are a frequent traveler on airplanes or spend a lot of time in public schools where knives are not allowed, try the ReedGeek. These unconventional scraping tools work well for finishing and adjusting the reed, no sharpening required!

Although it probably can’t replace your primary reed knife, the ReedGeek is great for making quick adjustments in a pinch or in situations where a reed knife is not allowed. It can be used on both single and double reeds (great for doublers!), and since it does not have a blade, it is safe for younger students to try adjusting their own reeds as well.

Additionally, the ReedGeek “The Bullet” is designed specifically for scraping synthetic reeds such as the Legere reeds. This tool works far better than a traditional reed knife for synthetic reeds.

See our detailed review of the ReedGeek tools.

Anatomy of a Reed Knife

The two main sections of a reed knife are the blade and the handle. Figure 2 below describes the more detailed terminology used for each area of a knife. From top to bottom these are:

- Tip: The end of the blade

- Edge: The cutting part of the knife. The edge is the part that gets sharpened and then bent to form the burr.

- Blade: The metal part of the knife that holds the edge

- Spine: The back edge of the blade opposite the cutting edge

- Tang: The metal extending from the blade into the handle. In a knife with a half tang, the tang goes halfway down the handle.

- Ferrule: A metal cap which connects the handle and the blade (not present on all knives).

- Handle: The portion of the knife designed for the reed maker to hold

- Butt: The end of the handle opposite the blade

The anatomy of the knife blade will also differ depending on the type of knife. All knife blades have a front and back face (the sides positioned towards the reed or towards you, respectively), which converge to form the edge (the sharp part of the knife used for scraping). Figure 3 shows an enlarged view of the blades of two types of reed knives.

Just above the edge, as shown on the left image in figure 3, is the relief. The relief is an area on the back face of the blade, which contributes to the ease (or difficulty) of sharpening and scraping. (Blodgett, p. 5)

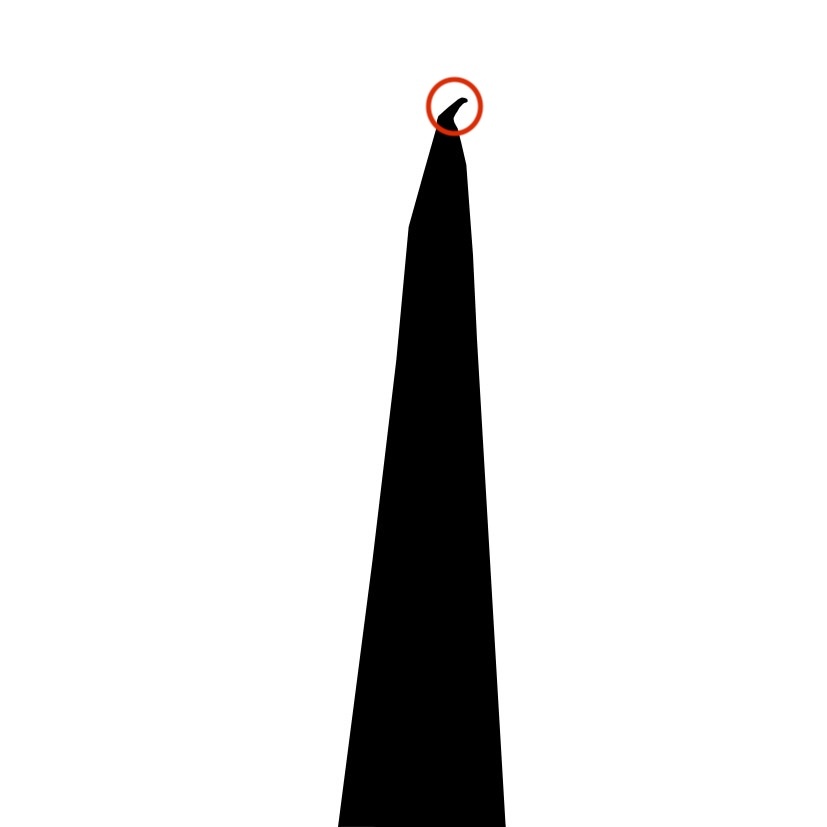

Figure 4 shows the burr, circled in red.

Steel Quality and Hardness

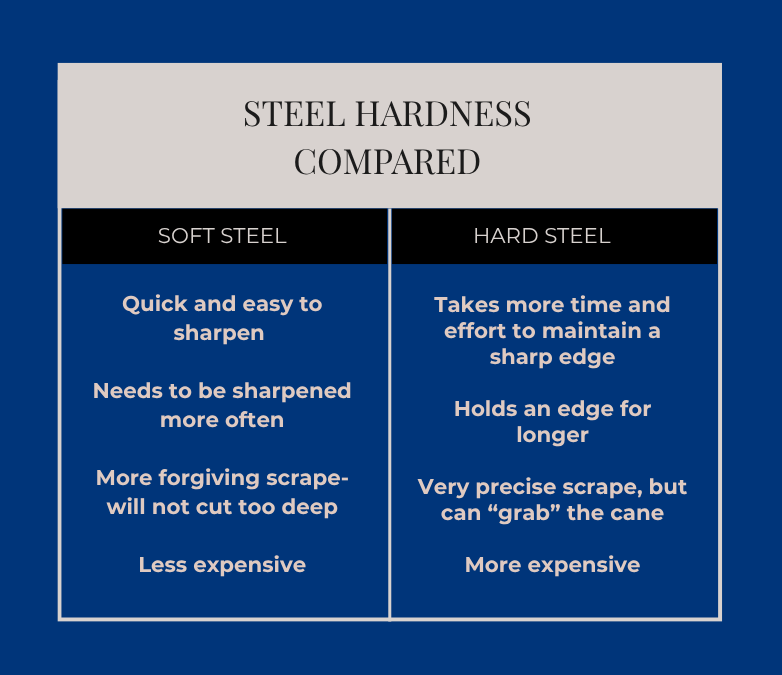

Reed Knives (with the exception of ceramic knives) are made from different types of steel or steel alloys. The hardness (also called quality) of the steel impacts the price point of the knife, as well as how the knife feels as it scrapes, how easy it is to sharpen, and how long it can hold a sharp edge.

The quality of steel is determined at the molecular level by chemical compounds called carbides, which form when carbon combines with another element. Under a microscope, carbides look like salt crystals- angular particles embedded throughout the steel. According to Corrosionpedia.com, iron carbides (composed of carbon and iron) are what contribute to the strength and hardness of steel. Other minerals may be added to create steel which is resistant to cracking, corrosion, and wear over time. Knifesteelnerds.com gives an in-depth explanation of this process.

Essentially, harder steels have smaller and more brittle carbides, which help a knife hold its sharp edge longer. Many reed knife manufacturers do not state a hardness. For a point of reference, generally German steels are on the softer end and the Japanese steels are on the harder end.

What hardness should I choose?

Keep in mind that even with various hardness levels available, a knife made from softer steel is still quite sharp and durable! We recommend focusing more on how the knife feels to use and what your budget is than the hardness label. Most of our knives that are made from harder steels are priced at $65 and up (with the exception of Landwell knives, which offer a choice of hard, medium, or soft). Most of the knives priced under $65 are made from softer steels. Table three below compares characteristics of hard and soft steels.

Still can’t decide? Medium hardness blades are a good compromise between the hard and soft steels, and are by far the most popular hardness option that we offer.

Handle Materials

Reed knife handles are made of either wood or plastic. Some brands offer a choice of wood for the handle,such as ebony, pearwood, rosewood, or olivewood. Designed to be ergonomic, knife handles are also tapered to either a round or square end. Figure 5 shows a rounded handle on the left and a square handle on the right.

Balance

A knife’s balance point refers to the placement of its center of gravity. Most people naturally grip their knife at or near the knife’s center of gravity. The farther away from the blade that the knife’s center of gravity is placed, the easier a knife is to control when scraping.

The knife style, handle material, length of the blade, and length of the tang all impact the placement of the knife’s center of gravity. Full tang knives tend to have a center of gravity farther down the handle than half tang knives. Because of the heftier blades, beveled knives tend to have a center of gravity closer to the base of the blade. The balance point will differ between brands. What matters most is that the knife feels comfortable to hold and use without excess pressure on the hand or wrist.

Right vs Left-Handed Setup

When choosing a new reed knife, be careful to select the correct right or left- handed option. Some knives come set up to be used by either right or left-handed people. For beveled knives this means that the bevel is on the right or left side of the blade. For double hollow ground knives, the burr has to be set in the correct direction. If a knife does not specify that it is right or left handed, it will need to be correctly sharpened before it can be used.

Check out our post on handing a knife (coming soon) for more details.

Sharpening

Properly sharpening a reed knife is crucial to making successful reeds, ensuring the longevity of the life of the knife, and keeping the user safe. A sharp knife should remove cane easily without the need for excessive force or tension. A dull knife will feel like it is not scraping efficiently and is also more prone to slip on the cane, possibly causing injury to the user. We recommend the Jende Knife Sharpening Book as an excellent resource for any reedmaker.

Our Recommendations

Top Sellers

This list is a side-by-side comparison of the top three most popular knives in each category, plus our overall most popular knife.

Beveled:

Rigotti Beveled Knife- $39.95

- Great quality for the price

- Ebony or pearwood handle

- Knife sheath included

Chang Beveled Knife- $110.95

- Easy to sharpen, holds and edge

- Smooth, precise scrape

- Durable leather sheath included

Jende Single Beveled Knife- $129.95

- Stainless steel ensures longer edge retention

- Designed to withstand the entire reedmaking process, from bark removal to finishing

- Tapered Madagascar Ebony handle

Double Hollow Ground:

Landwell- $112.95

- Three steel strengths available

- Ease of sharpening and edge retention depends on steel hardness choice

- Knife sheath included

Chang- $99.95

- Designed for balance and comfort

- Easy to sharpen, designed to last over many sharpenings

- Durable leather sheath included

Jende Original- $99.95

- Made from strong yet durable Japanese steel

- Lightweight without sacrificing scraping control

- Sharpens easily while still holding an edge

Most Popular Overall:

Chiarugi Razor Knife- $48.95

- Tempered and grounded steel blade

- Five handle options, including ebony, olive, pearwood, rosewood, and walnut

- Knife sheath included

Conclusion

Ultimately it is up to the individual to determine what knife works best for them. After using this post as a starting point, it may be helpful to consult a teacher, friend, or colleague.

If you are a professional who is thinking of changing styles or adding a knife to your tool kit, make a list of what you like and do not like about the knife you currently use. Look through our discussion of the pros and cons of each style and pick one that has the potential to solve whatever issue you may be having. Please refer to our reed knife chart to figure out which knife works best for you.

As always, please feel free to contact us. We’re happy to help you!

Works Cited

Blodgett, B. Thomas. The Jende Book of Sharpening. USA: Jende Industries, LLC, 2008.

“Carbide” Corrosionpedia.com, July 19th 2024. https://www.corrosionpedia.com/definition/209/carbide#:.

Thomas, Larrin.“Carbide Types in Knife Steels” KnifeSteelNerds.com. July 15th, 2019. https://knifesteelnerds.com/2019/07/15/carbide-types-in-knife-steels/#:.

“What is a burr?” scienceofsharp.com, January 11th 2025. https://scienceofsharp.com/2015/01/11/what-is-a-burr/.